Featured Projects

What's happening

Contact us

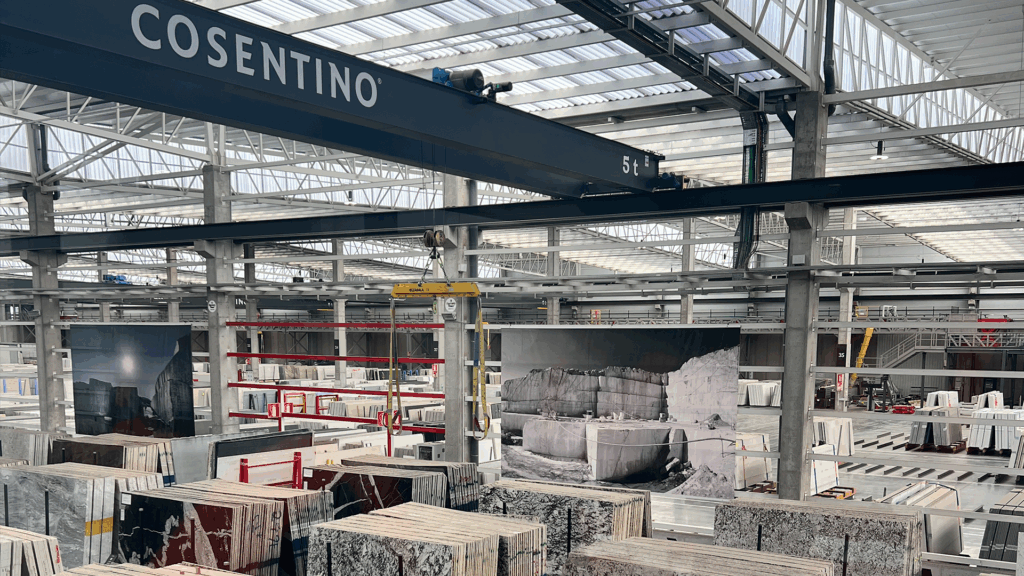

This month our Senior Director, Annie Conway, had the opportunity to travel to Granada, Spain with Cosentino and industry colleagues for an incredible tour of the Cosentino factory.

The trip included a deep dive into Cosentino’s materials, processes, and technology. The group saw firsthand how Dekton, Silestone, and other surfaces are sourced, engineered, tested, and distributed. We also had the opportunity to visit one of their quarries and see their natural stone at the source. Seeing both the engineered and natural stone lifecycles side by side offered invaluable context for how these products ultimately perform in the built environment.

Why it matters:

As a general contractor, JDL is relied on to provide clarity around material performance, lead times, fabrication tolerances, installation sequencing, and long-term maintenance. Experiencing the manufacturing and extraction processes up close allows us to give clients more accurate guidance, better anticipate field conditions, and ultimately deliver a smoother, more predictable project with the highest quality.

What it means for our clients and design partners:

A huge thank you to the Cosentino team for the hospitality and for giving us a behind-the-scenes look at how these products come to life. Experiences like this directly strengthen the value we bring to our projects, our partners, and our clients.